The guarantee of satisfaction throughout the life of your investment.

Analis offers to the users of Beckman Coulter centrifuges and ultracentrifuges a rotor inspection FRIP program to ensure longevity and safety of equipment and the following services linked to centrifugation:

- Prevention Program - FRIP: Field Rotor Inspection Program

- Training for best user practices

- Advices on the equipment choice and for parameter optimization

- Advices for balancing your rotor

These inspections prevent accidents and prevent premature damage on rotors due to:

- Stress corrosion

- The fatigue of the material

- Wear or damage to the coating

An accredited technician inspects each rotor cavity for signs of wear and deterioration. Recommendations are also made on the need to replace safety systems and seal lubrication systems.

A report on the condition of the rotors and the possible limitations of use is sent to you at the end of the inspection. If you wish to benefit from one of these services or to receive more information, contact us.

USER TRAINING PROGRAM

Analis Academy - Education session

Training for best user practices

can be organized in your or our facilities. Objectives of this training:

- Safe centrifuge use

- Maximum lifetime warranty of your investment

- Avoiding unbudgeted expenses

The content of these courses, although adaptable according to your needs, is articulated as follows:

- Proper use and handling of rotors

- Good use of tools

- Care and maintenance of rotors

- Optimal choice of tubes

- After sales support

- Out of warranty for rotors and decommissioning

CHOOSE THE RIGHT ROTOR

Advices on the choice of rotors, tubes,

accessories and optimization of centrifugation parameters.

Our centrifuge product ranges

Build your centrifuge configuration

Calculating K-Factor

BALANCE YOUR ROTOR

In order for a rotor to run smoothly and safely at its operating speed, the load it carries must be balanced.

A rotor can be properly balanced by following some simple rules: see advices below

ADVICES TO BALANCE YOUR ROTOR

A rotor can be properly balanced by following some simple rules:

- A rotor must never be run with buckets missing, although opposing buckets may be left empty.

- All opposing loads must balance within a certain weight as specified by the centrifuge manufacturer’s instruction manual.

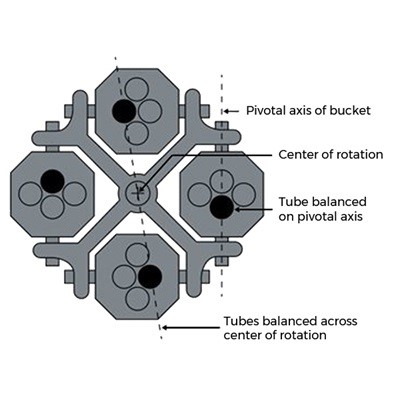

- If opposing buckets are run with a partial load of tubes in their adapters, these tubes must be arranged symmetrically, both with respect to the pivotal axis of each bucket and across the center of rotation. With some partial loads, it may be difficult or impossible to achieve the correct symmetry in both sets of opposing buckets. The simplest solution is to fill one or more tubes of the same size with water, or a denser liquid if necessary, and use them to balance the load symmetrically.

Most centrifuges are equipped with an imbalance detector which turns the centrifuge off before any eccentric rotation caused by a load imbalance can damage the drive shaft or bearings. However, the improper distribution of tubes in carriers or adapters can cause poor separations even if the imbalance isn’t severe enough to trigger this detector. In these situations, the buckets won’t pivot to the required horizontal position during the run, resulting in poor density separations or re-mixing of sedimented material during deceleration. Also, the possibility of tube breakage during the run is greatly increased when the buckets are not horizontal at operating speed.

You may notice that the centrifuge vibrates when the rotor is accelerating or decelerating at low speeds. This is normal, and occurs as the rotor passes through a so called critical speed range where any small vibrations are temporarily amplified. Your separations will not be disturbed during deceleration, because the centrifugal force is still high enough to stabilize them. However, you should not select an operating speed within the range where these exaggerated vibrations occur. Your instruction manual will tell you what speeds to avoid.

Correct symmetry when balancing a partial load

A Top View of a Horizontal Rotor

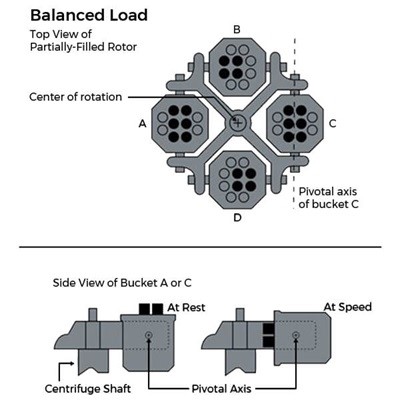

Example of a balanced load:

Assuming all tubes have been filled with an equal amount of liquid, this rotor load is balanced. The opposing bucket sets A-C and B-D are loaded with an equal number of tubes and are balanced across the center of rotation. Each bucket is also balanced with respect to its pivotal axis.

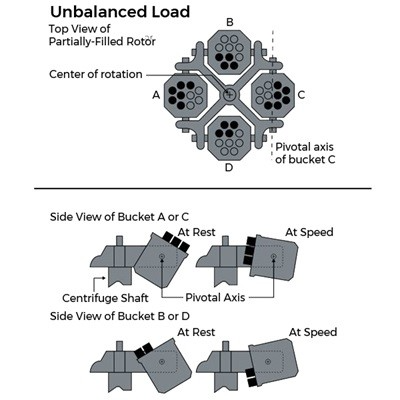

Example of an unbalanced load:

Even if all the tubes are filled equally, this rotor is improperly loaded. None of the bucket loads are balanced with respect to their pivotal axes. At operating speed, buckets A and C will not reach the horizontal position. Buckets B and D will pivot past the horizontal. Also note that the tube arrangement in the opposing buckets B and D is not symetrical across the center of rotation.

At every stage, our experts provide personalized support.

Expertise & Services: Empowering Your Success. Learn more

Consultancy

to find the smart technology

Pre-installation

Installation

Maintenance

Preventive

& Corrective

Validation & Qualification

IQ/OQ - PQ

Evaluation & Audit

Application support

Quality & Excellence: A Commitment

At ANALIS, excellence is a commitment shared by each of our employees, driven by a continuous improvement mindset to satisfy all our clients: clinical, industrial, and research laboratories.

Respect, excellence, and passion are the core values deeply embedded in our DNA.

We also prioritize

environmental respect and reducing our ecological impact as part of our

commitments. We strive to engage as long-term partners with both our suppliers

and clients. Contributing to research and improving health and quality of life

through the implementation of cutting-edge technologies in laboratories is also

a crucial part of our mission.

That's why we have teams of experts and service

engineers specialized in each laboratory segment and application area, allowing

for a personalized approach with integrated solutions in every laboratory. Our

vision is to position ourselves as a "Label of Quality" for each

laboratory, which remains one of our daily challenges.

Vincent Luyckx

Analis CEO

Jean Marie Cornet

Technical Service Manager

Céline Misson

Sales Contracting Specialist